Laser tacho probe and Panel Tachometers

Laser tacho probe,Tachometer Sensors,Optical Sensors,

Tachometers and Speed Transmitters require a permanently mounted speed sensors that observe a target on the machines rotating shaft. Several types of sensors are available including Proximity, Hall Effect (magnetic), Optical and Laser. Permanently mounted systems usually use a Proximity or Hall Effect type sensor. Laser and Optical Sensors are more suited for portable equipment and special applications. Optical Sensors work well with “Reflective Tape” as a target on the shaft but are not recommended for permanent installation as the sensor may become dirty over time or the tape may come loose.

To create the “speed pulse” required by the Tachometer to calculate RPM either a Proximity or Hall Effect Sensor is mounted to observe a Keyway or Speed Gear Wheel mounted on the machines rotating shaft. While Keyways generally create a once per turn pulse speed gears may produce 10, 30, 60 or 100 pulses (teeth) per revolution. For highly accurate and low speed readings a Speed Gear with multiple pulses per revolution is preferred. For balancing a “once per turn” pulse is preferred.

Panel Tachometers LUYOR-908 and LUYOR-910

Panel Mount Tachometers are used to measure RPM, measuring conveyor speed, motor speed and many other applications. They can be custom programmed to fit your application. Rugged and reliable, our 1/8 din panel mount tachometers are designed for both the OEM and retrofit markets and are suitable for a broad range of applications. From the economical LUYOR-908 to the sophisticated yet affordable LUYOR-910 with optional output modules, panel tachometers are engineered to meet the strictest tolerances.

Laser tacho probe,Tachometer Sensors

902 澄清度檢查法

902 澄清度檢查法

注射劑、眼用液體制劑可見異物檢查法

注射劑、眼用液體制劑可見異物檢查法

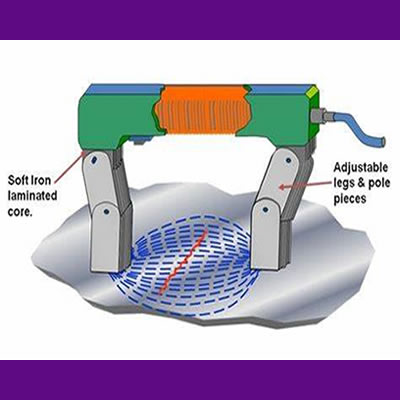

飛利浦PHILIPS DUV-35W紫外線燈泡配高強(qiáng)度磁粉探

飛利浦PHILIPS DUV-35W紫外線燈泡配高強(qiáng)度磁粉探

磁粉檢測的常見的錯(cuò)誤認(rèn)知

磁粉檢測的常見的錯(cuò)誤認(rèn)知